Conquer Your Next LEGO Challenge with Mould King Liebherr LR 13000

Are you ready to dive into the world of construction and heavy machinery? Let us take you on a journey back in time to the creation of one of the most powerful cranes ever built.

The Liebherr LR 13000 crane was developed by the German company Liebherr in 2010 and quickly became a renowned engineering marvel. Its impressive lifting capacity of over 7800 pounds and unmatched height of over six feet caught the attention of construction enthusiasts worldwide.

With time, the crane became a symbol of power and sophistication in the heavy machinery industry.

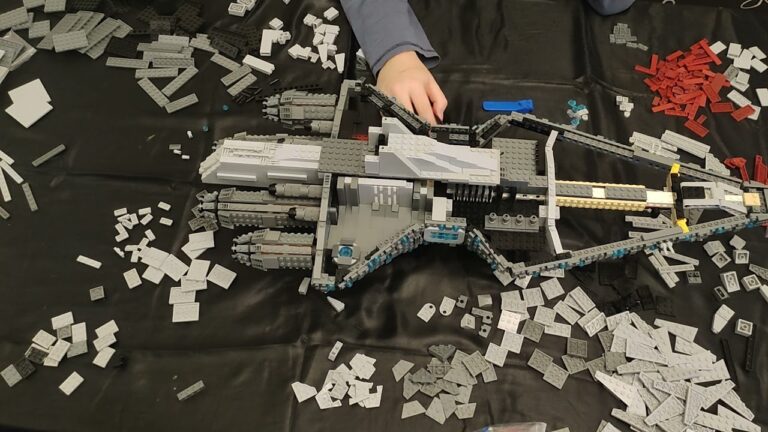

Now, the Mould King Liebherr LR 13000 building kit provides an opportunity for enthusiasts to experience the thrill of building and operating this extraordinary crane themselves. With over 4000 pieces and incredible attention to detail, this kit offers an unparalleled authentic building experience. So, are you ready to take on the challenge and build your own Liebherr LR 13000 crane with the Mould King building kit? Let’s get started!

Start Assembly Liebherr LR 13000

Building the Liebherr Crane is a rewarding but complex process, requiring patience and attention to detail. It is important to take the time to fully understand each step of the process in order to create a functional and impressive model. Let’s take a closer look at each step:

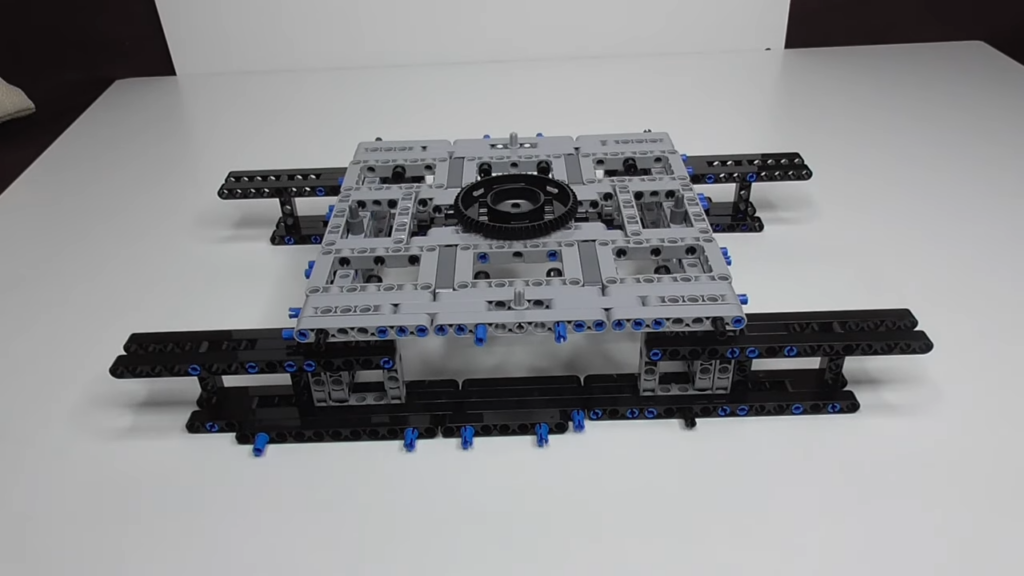

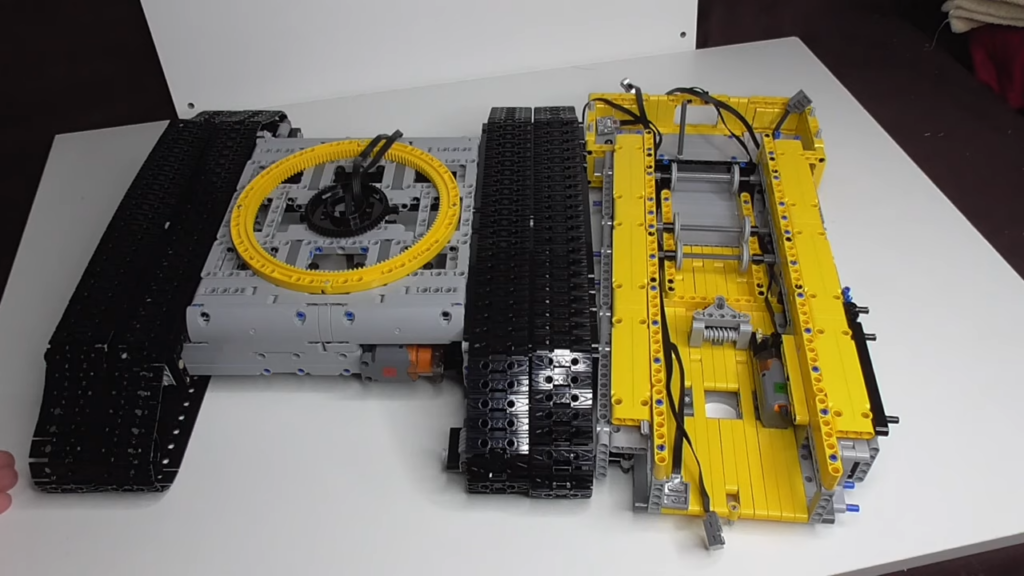

Step 1: Middle Base Construction

The first step in building the Liebherr Crane involves constructing the middle base. This is done by assembling the small and big technic frames to form a solid foundation. The next step is to attach the big gear and a lot of 13 and 15 length technic beams to the base to ensure stability.

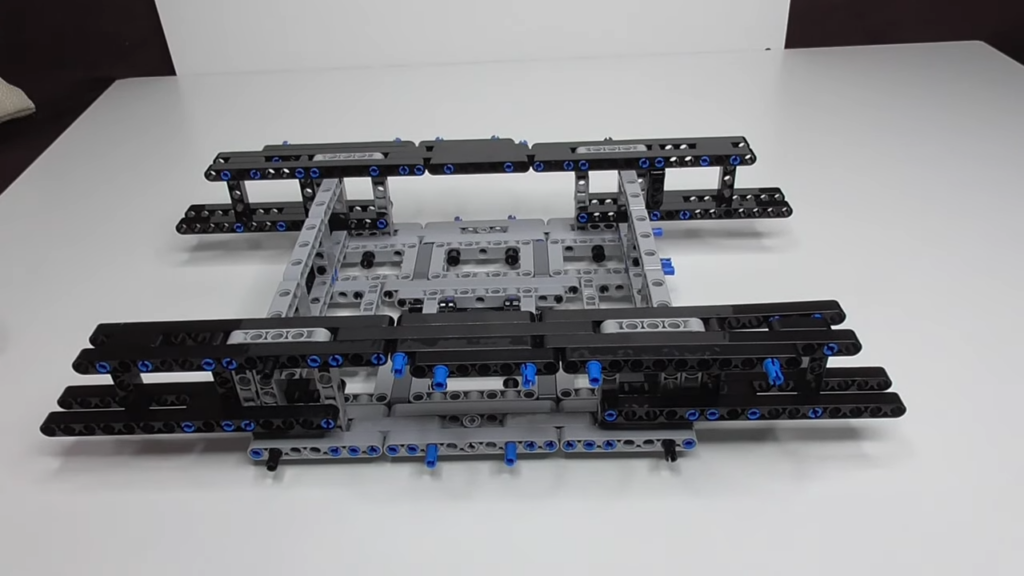

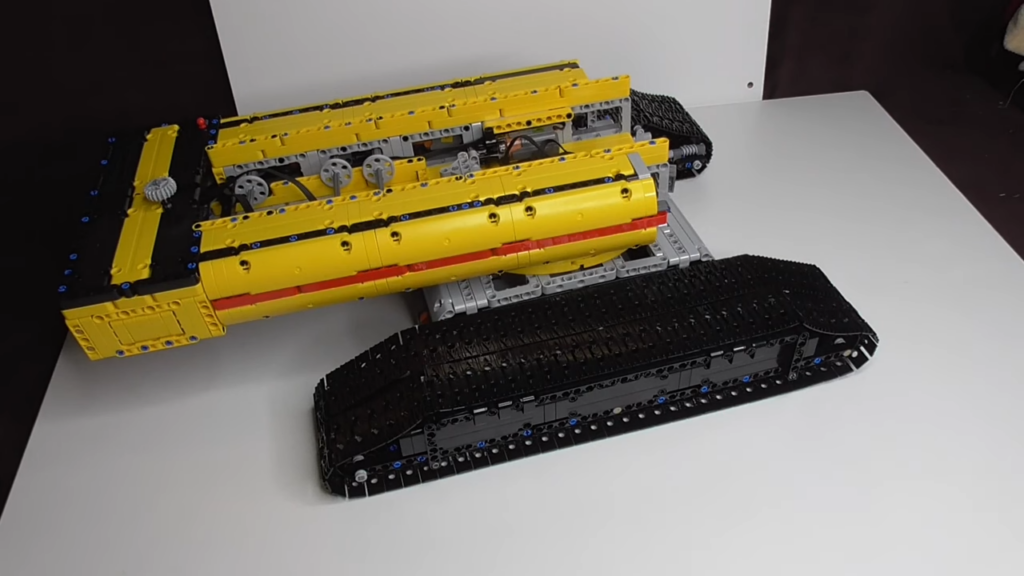

Step 2: Motor and Wheel Assembly

The second step involves installing the first two L motors, one for each chain, and a lot of stabilization. The first parts of the wheels for the tracks are also assembled in this step. It is important to take your time during this step, as the motor and wheel assembly will be the foundation for the rest of the crane.

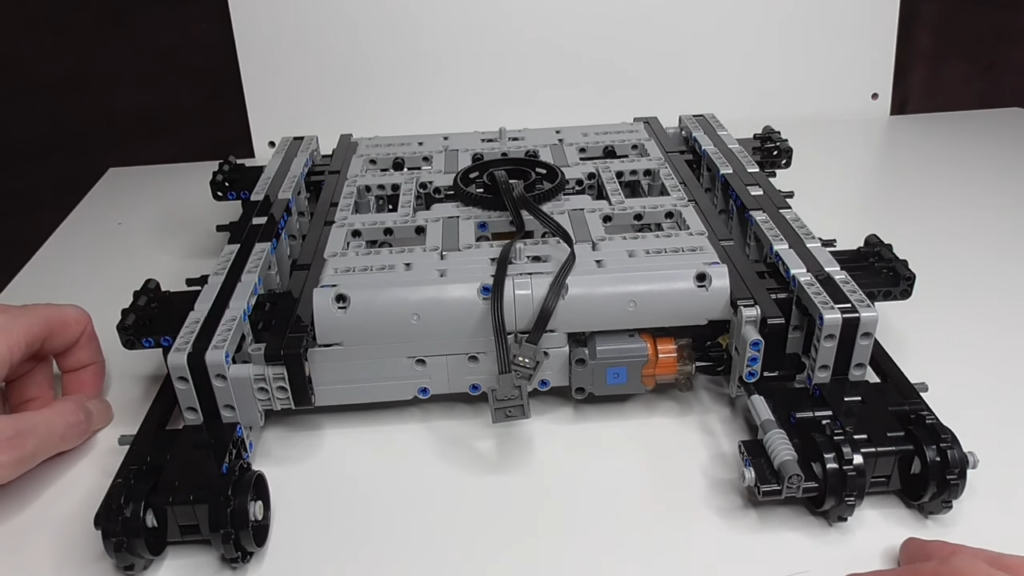

Step 3: More Support for the Tracks and the Middle Part

In the third step, the 280 tracks are assembled and placed onto the vehicle. The second part of the turntable is connected with the turn gears, and technic beams, panels, and frames are used to build the middle part of the crane. This step is crucial in ensuring the stability and functionality of the crane.

Step 4: Basket and Motor Installation

The fourth step involves attaching three L motors to the middle part of the crane and building the basket, which will be used to lift heavy objects. It is important to make sure the black gear has good contact with the technic beam to prevent friction. Cord management is also important at this stage, with two extension cables needed for the L motors underneath on one side, and the motor cable on the other side. Finally, the box for the chords is attached to the back.

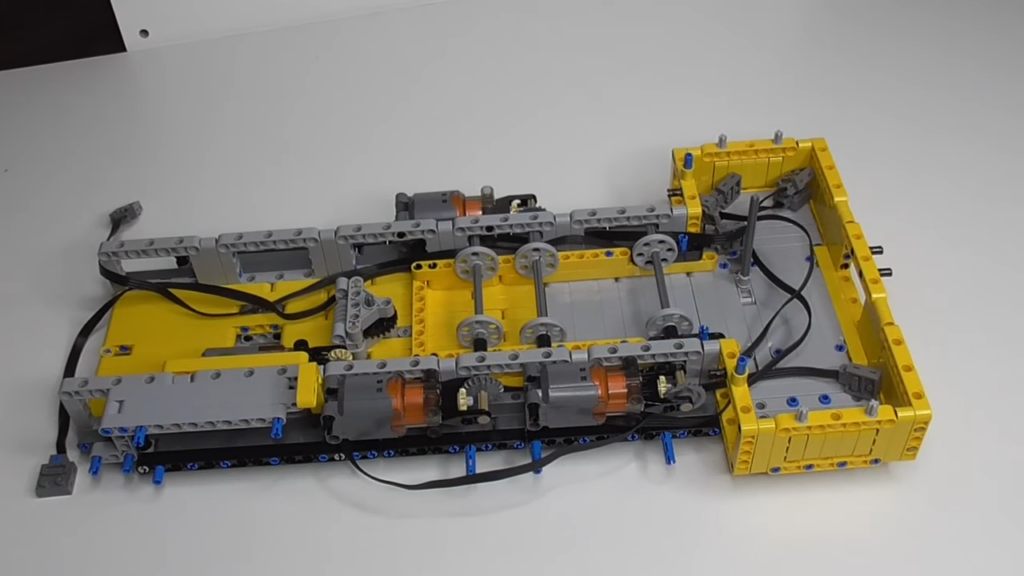

Step 5: Connection of Mechanical Parts and Cord Management

The fifth step involves connecting the chords to the power functions, installing the big turntable, and putting the side covers and panels on both sides of the crane. Cord management is important at this stage, with the battery box placed inside the rear part of the crane.

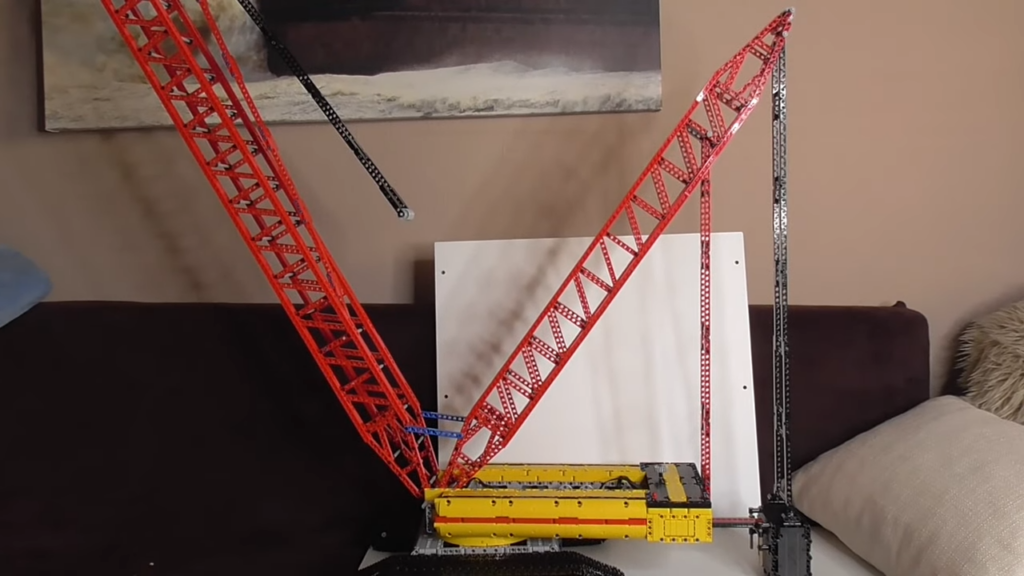

Step 6: Attachment of Rear Extension and Final Assembly

The final step involves attaching the rear extension to the crane to give it more width and height, using blades and technic beams to assemble the rest of the crane, and following the instructions to complete the assembly. It is important to be patient and take your time with each step to ensure the crane is built properly.

Note: Building the Liebherr Crane can be repetitive, but the end result is worth it. Be patient and take your time with each step.

Impressive Build with Room for Improvement

As a diligent reviewer, I am here to provide an unbiased review of the Mould King LR 13000 model kit. Let’s start with the positive aspects of this building kit:

Positives

– Fast delivery

The kit arrived within just 5 days, even though it was estimated to take about 14 days for delivery. This ensured that the wait time for the product was significantly reduced.

– Good physical packaging

The actual Mold King product packaging was nice and in good condition. However, it was a little dented due to the flimsy outer box used for shipping. This did not cause any damage to the kit, but collectors may find this a little disappointing.

– All motors work flawlessly

All the motors in the kit worked perfectly well and could be started steplessly, not just on/off. This is a testament to the high quality of the motors and the attention to detail involved in their development.

– All parts were included in the kit

It was a pleasant surprise that all the parts were included in the kit and there was no need to reorder anything. This reliability in supply chain management by Mould King is commendable.

– Impressively strong clamping force

One of the most impressive aspects of this model is the strength of its clamping force. The stone clamps create a secure and stable build that can withstand the high complexity and size of the model. Once fully constructed, it is highly resistant to small knocks and bumps, making it a great display piece that won’t easily fall apart.

– Thoughtful packaging

The Mould King LR 13000 model comes in several bags, each of which is further divided into sizes and construction sections. This level of organization is truly thoughtful and makes the building process less confusing and enjoyable. It ensures that the builder maintains focus on constructing the model rather than fussing around trying to find the right pieces.

– Clear and Comprehensive instructions

The instructions for building the model are clear and comprehensive, with approximately 676 construction steps. While some aspects may not be clear at first, the general organization and level of detail is quite good. The instructions enable builders to work through the construction process with minimal confusion.

Negatives

– Wheels of predatory drive grind against the frame

While assembling the model, I noticed that the wheels of the predatory drive would grind extremely against the frame. To address this issue, I had to use sandpaper to sand down the wheels a bit.

– Important gear is too close to the frame

I also experienced an issue where an important gear was too close to the frame. This made it practically impossible to turn, making it frustrating to continue the assembly process. To fix this issue, I had to cut a small part out of the frame to make room for the gear. This might require skill and additional tools that might not be available to every builder.

– Lack of connection between substructure and superstructure

The entire substructure and superstructure are one piece each and are just placed on top of each other without any connection, meaning that the whole model is held together solely by gravity. While this works fine when the model is not moved, I found that any significant movement of the model could cause the entire model to collapse.

– Model is exceptionally heavy

The Mould King LR 13000 model is an extremely heavy model, weighing approximately 6kg in total. This weight leads to high force in every single part of the model. As a result, the model collapsed twice during the building process, especially when I moved the crane boom far forward. The superstructure would tilt forward, causing everything to fall apart, with the cables still hanging and blocking. Rebuilding it was a struggle.

Overall, this model is a great value for its price, and construction enthusiasts will enjoy the fun that comes with building and proudly displaying such a grand piece.